| |

|

| Add: |

Rugao City, Jiangsu Province, China |

| PC: |

226500 |

| Tel: |

+86-513-87628369

|

| Fax: |

+86-513-87635890 |

| Mobile: |

+86 13962724758 Franks Cao

+86 13626278212 Aileen Chen |

|

|

|

CNC Multi Axis Air Coil Winding Machine For Heavy-duty Bobbinless Coils |

|

|

| Product name:CNC Multi Axis Air Coil Winding Machine For Heavy-duty Bobbinless Coils |

| Item:2-14 |

| Details: |

| |

I Description of CNC multi axis air coil winding machine

There are two machines for heavy-duty bobbinless coils, one is for 1.0mm~2.0mm, another is for 2.0mm~4.0mm. Both can produce round wire air coils and flat wire air coils.

They are CNC control, industrial computer operation, 3-axis full servo drive.

They can also be called as flat wire coil winding machine.

|CNC air coil winding machine|CNC air coil winder|CNC bobbinless coil winding machine| CNC bobbinless coil winder|

II Main features of CNC multi axis air coil winding machine

- Adopting high precision ball screw and bearings from Korea, higher winding & guiding precision, longer machine life.

- Heavy duty for large size round and flat wires, max. 4mm

- All three axes are servo motor control, low noise, stable running

- CNC control system adopts SAMSUNG microcontroller, simple operation, easy programming

- Optional wire stripping machine and tinning device

- Optional full seal protection cover |CNC air coil winding machine|CNC air coil winder|CNC bobbinless coil winding machine| CNC bobbinless coil winder|

|CNC air coil winding machine|CNC air coil winder|CNC bobbinless coil winding machine| CNC bobbinless coil winder|

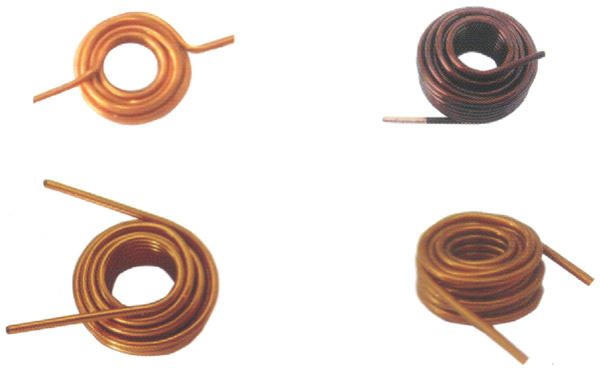

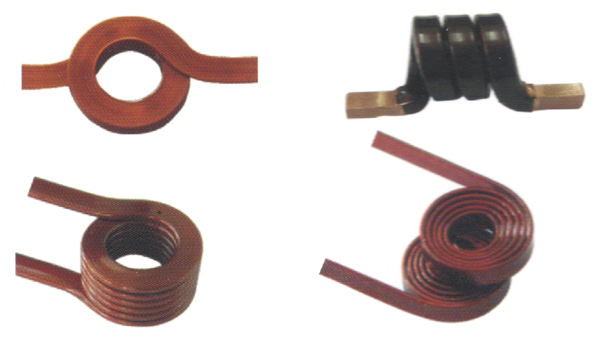

III Photos of bobbinless coils made by CNC multi axis air coil winding machine:

|CNC air coil winding machine|CNC air coil winder|CNC bobbinless coil winding machine| CNC bobbinless coil winder|

IV Main technical data of CNC multi axis air coil winding machine

|

No.

|

Item

|

KXJ-033

|

KXJ-033A

|

|

1

|

Winding wire range

|

1.0-2.0mm

|

2.0-4.0mm

|

|

2

|

Suitable air core coils

|

Referring to attached photos.

|

|

3

|

Stripping method

|

3 diamond blades, centrifugal type

|

Servo stripper

|

|

4

|

Max. stroke of guide head

|

65mm

|

|

5

|

Lead length

|

30mm

|

|

6

|

Lead position

|

Arbitrary

|

|

7

|

Spindle speed

|

0-3000 rpm

|

0-1500 rpm

|

|

8

|

Max. production speed

|

50 pcs/min

|

30 pcs/min

|

|

9

|

Air coil winding direction

|

Clockwise / anti-clockwise

|

|

10

|

CAM axis driving motor (X-axis)

|

AC900W, servo

|

AC2700W, servo

|

|

11

|

Winding spindle motor (Y-axis)

|

AC750W, servo

|

AC 1500W, servo

|

|

12

|

Wire guiding motor (Z-axis)

|

AC 750W, servo

|

|

13

|

X-axis setting range

|

0.1º-359.9º

|

|

14

|

Y-axis setting range

|

±0.1º - ±99C359º

|

|

15

|

Winding spindle stop precision

|

0º

|

|

16

|

Winding set resolution ratio

|

0.1º

|

|

17

|

Stripping motor

|

AC 150W

|

|

18

|

Tinning oven power

|

400W

|

|

19

|

Electric power supply

|

Single phase 210~230V, 50Hz

|

|

20

|

Compressed air pressure

|

0.5~0.7MPa

|

|

21

|

Machine dimension

|

1720 x 730 x 1510mm

|

1100 x 1000 x 1700mm

|

|

22

|

Machine weight

|

250kg

|

500kg

|

|CNC air coil winding machine|CNC air coil winder|CNC bobbinless coil winding machine| CNC bobbinless coil winder|

|flat air coil winding machine| flat air coil winder| flat bobbinless coil winding machine| flat bobbinless coil winder| |

|

←[Previous:2-15]

[Next:2-13]→

|

|

|