Amorphous transformer is new developed with amorphous core which has no-load loss 20% less than conventional CRGO cores!

We can provide complete machines for producing amorphous transformers, and technology support as well.

I Amorphous Cutting Machine

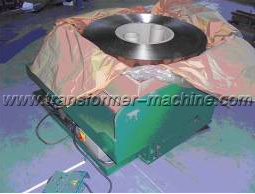

II Amorphous Coil Overturn Platform

II Amorphous Coil Overturn Platform

Because amorphous alloy is very soft, the coil can’t be erected itself. When amorphous alloy coils arrives workshop, they are horizontal.

This overturn platform is for erecting coils for loading onto decoilers of the amorphous cutting machine.

● Max. coil weight: 1T

● Hydraulic station motor power: 1.5kW

● Overturning degree: less than 90 degree

●Dimension: 1300 x 1300 x 700mm

●Weight: 550kg

III Three-head Decoiler

●For loading silicon steel coils, automatically decoiling & recoiling

●Width of silicon coil: 142-213mm

●Bearing weight of each head: not less than 1T

●Decoiling & recoiling speed: adjustable

IV Annealing furnace

●Whole dimension: 2250 x 1900 x 2360mm

●Annealing room size: 1500 x 1500 x 1700mm

●Max. temperature: 450℃

● Rated power: 78kW, 3 phase

●Heating duration: less than 3 hours

●Temperature eveness: +/-10℃

●Separate temperature control system (PID), 30-section programmable temperature controller, with over-temperature shut-off and over-temperature alarming functions.

●Each phase of heating tube has 200A fuse and three current meters, separate control switch

● Equipped with 6 temperature sensor with numerical displaying, one for body itself, five for detecting product

●Furnace is filled with nitrogen gas. Start/stop filling is controlled by electromagnetic valve which is PLC programable.

V Coil Winding Machine

Description

Description

This series winding machines are analog to Japanese machine, special designed by ourselves for winding coils used in amorphous transformers with Patent in China.

It can wind three coils simultaneously with separate wire arranging device. And so turns in each layer and tensions are same in three coils. Thus can achieve electric testing parameters of three coils be same!

Specifications

|

Code

Item

|

FRXJ-315A

|

FRXJ-650A

|

|

Center height of spindle(mm)

|

1070

|

1070

|

|

Output torque of main spindle(N/m)

|

800

|

1000

|

|

Spindle output speed range (r/min)

|

Low-gear: 0-100

High-gear: 0-180

|

Low-gear: 0-57

High-gear:0-115

|

|

Spindle motor power(kW)

|

5.5

|

7.5

|

|

Servo motor for wire arranging(kW)

|

0.75

|

1.0

|

|

Pre-set program numbers

|

15

|

|

Automatic winding turns

|

0-9999.9

|

|

Turn displaying precision

|

0.1

|

|

Automatic wire arranging width(mm)

|

3×400

|

3×500

|

|

Wire arranging pitch(mm)

|

0.1-99.99

|

|

Size of pneumatic expanding die range(mm)

|

Min 85 x (134-154)

Max 190 x (220-240)

|

|

Working air pressure needed (MPa)

|

0.2-0.6

|

|

Max. coil diameter(mm)

|

500

|

600

|

|

Dimension of main machine(mm)

|

3500×1000×1200

|

4000×1100×1200

|

Main configuration

3.1 Main spindle driving motor: from Taiwan, inverter control

3.2 Inverter: Danfoss brand, from Denmark

3.3 Wire arrangement is PLC control, servo drive; PLC is Panasonic, servo motor is Fuji from Japan

3.4 Linear guide, ball screw, linear bearing and movement slick rod are all from Taiwan

3.5 Operations are on touch screen (HMI) from Panasonic Japan

3.6 Three separate tension devices, pneumatic driven, with magnetic arresters

3.7 Tail stock is pneumatic driven

3.8 Winding die is pneumatic expanding

3.9 Run-out roller table is motorized.

VI Tunnel Type Baking Oven for Epoxy Resin Coating

● Usage: for quickly solidifying epoxy coatings on core surface

●Heating temperature: not more than 150 degree, adjustable

●Inner cavity height: not less than 300mm

VII Double-head Core Overturn Platform

●Max. core weight: 1T

●Hydraulic station motor power: 1kW

●Dimension: 2200 x 1100 x 1100mm

●Weight: about 750kg

VIII Core Testing Equipment

● For testing performance of amorphous core

●Working current: 50Hz, AC220V

●Output: testing voltage, no-load loss, magnetizing current, magnetizing voltage/current

IX Amorphous Body Assembling Table

Description

This equipment is specially designed for assembling amorphous transformer body.

First lay three coils on the lifting platform, insert cores into coils, close the core, assemble insulation and clamp the whole body.

The platform height is adjustable for different processes.

This equipment is driven by hydraulic, very stable and convenient for adjustment.

Specifications

- Working height: 850mm

- Suitable body dimension:

Length: 700-1600mm

Width: 360-700mm

Height: 400-900mm

- Rated bearing weight: 3000kg

- Lifting stroke of platform: 500mm

- Lifting speed: 40mm/s

- Hydraulic pressure: 21MPa

- Total power: 2kW

- Total weight: 1500kg

- Dimension: 3000 x 2000 x 1250mm