| |

|

| Add: |

Rugao City, Jiangsu Province, China |

| PC: |

226500 |

| Tel: |

+86-513-87628369

|

| Fax: |

+86-513-87635890 |

| Mobile: |

+86 13962724758 Franks Cao

+86 13626278212 Aileen Chen |

|

|

|

Amorphous Transformer |

|

|

| Product name:Amorphous Transformer |

| Item:9-3 |

| Details: |

| |

Description

SBH15-M series amorphous alloy core transformer is made according to Chinese standard, equals to IEC standard. No-load loss of this series transformer is 75% less than that of CRGO distribution transformer.

Structure features

-Amorphous alloy is a new strip material which has no crystal structure and so its magnetizing power is small, high resistivity, low eddy current loss.

- Core is of wound core structure, three-phase 5-column type, section is rectangular.

- Coil is rectangular, HV winding is wound by enameled wire; LV winding is wounded by foil, increased short-circuit throughput!

- Transformer connecting symbol adopts Dyn11, avoiding influence by high harmonic, stronger un-balanced load resisting capability.

- Vacuum oil filling avoids gas in windings completely

- Deletes oil conservator, adopts fin type radiator for cooling

Performance Parameters

|

Rated voltage: 6, 6.3, 10, 20 / 0.4KV

|

|

|

Rated tapping range: ± 5% or ±2×2.5%

|

|

|

Rated frequency: 50Hz (60Hz can be specially ordered)

|

|

|

Connecting symbol: Dyn11

|

|

|

Rated Capacity

(kVA)

|

No-load loss

(W)

|

No-load current

(%)

|

Load loss

(W@75℃)

|

Short-circuit impedance

(% @75℃)

|

Weight

(kg)

|

Dimension

(mm)

L x W x H

|

|

| |

| |

|

50

|

43

|

1.3

|

870

|

4

|

460

|

1035

|

600

|

925

|

|

|

80

|

60

|

1.1

|

1250

|

600

|

1150

|

600

|

980

|

|

|

100

|

75

|

1

|

1500

|

660

|

1090

|

755

|

985

|

|

|

160

|

100

|

0.7

|

2200

|

920

|

1290

|

710

|

1040

|

|

|

200

|

120

|

0.7

|

2600

|

990

|

1220

|

885

|

1050

|

|

|

250

|

140

|

0.7

|

3050

|

1195

|

1370

|

920

|

1100

|

|

|

315

|

170

|

0.5

|

3650

|

1335

|

1265

|

1045

|

1085

|

|

|

400

|

200

|

0.5

|

4300

|

4/4.5

|

1585

|

1390

|

1180

|

1130

|

|

|

500

|

240

|

0.5

|

5150

|

1765

|

1390

|

1120

|

1195

|

|

|

630

|

320

|

0.3

|

6200

|

4.5

|

2400

|

1520

|

1185

|

1355

|

|

|

800

|

380

|

0.3

|

7500

|

2950

|

1885

|

1215

|

1470

|

|

|

1000

|

450

|

0.3

|

10300

|

3500

|

1955

|

1310

|

1565

|

|

|

1250

|

530

|

0.2

|

12000

|

4100

|

2025

|

1310

|

1675

|

|

|

1600

|

630

|

0.2

|

14500

|

5550

|

2535

|

1345

|

1830

|

|

|

2000

|

750

|

0.2

|

17400

|

5

|

6120

|

2595

|

1595

|

1985

|

|

|

2500

|

900

|

0.2

|

20200

|

5

|

8600

|

2950

|

1685

|

2500

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Notes

|

1. Short-circuit impedance of 400/500 KVA transformers @ 10KV and less is 4%; that @ 20kV is 4.5%.

|

|

|

2. LV winding of 50 KVA and100KVA transformers are not foil type coils.

|

|

|

3. Special sizes or requirements can be discussed and special designed.

|

|

Insulation Level

|

Voltage Class

(kV)

|

Max. Effective Voltage

(kV)

|

Rated short-duration frequency voltage (kV/min)

|

Rated full-wave peak lightning impulsive voltage (kV)

|

|

≤1

|

≤1.1

|

5

|

/

|

|

6

|

7.2

|

25

|

75

|

|

10

|

12

|

35

|

95

|

|

20

|

24

|

50

|

120

|

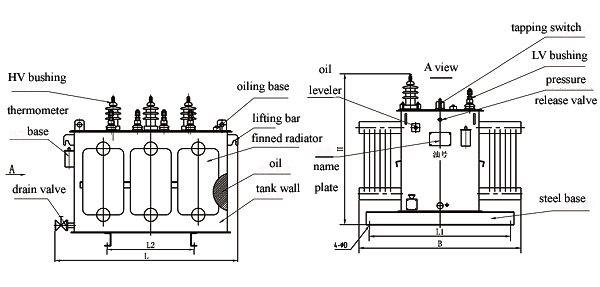

Transformer Outline

|

|

←[Previous:9-5]

[Next:9-2]→

|

|

|